Meet Tricia Carey of Lenzing Fibers

Denim Panel with Rivet 50, © Bluezone

Lenzing Fibers is on a mission to create innovative textiles that preserve resources and protect our planet. Responsible for natural wood-based fibers like TENCEL™, Lenzing focuses on improving environmental performance throughout the value chain.

Humanity faces challenges too complex to be solved by business as usual. With this in mind, Lenzing is countering the wastefulness of business as usual with circular economy models and new technologies like REFIBRA™.

Now, in the middle of one of the most significant challenges that many of us have faced in our lifetimes, companies like Lenzing are more important than ever. As the Director of Global Business Development of Denim at Lenzing, Tricia Carey plays a key role in the company’s decision-making processes and the future of the apparel industry as a whole. We spoke to her about the importance of sustainable innovation and her post-pandemic predictions.

Hometown / Favorite Food:

New York City / Chips and Salsa

Describe yourself in 3 words:

Passionate, enthusiastic, personable

What does sustainability mean to Lenzing?

Sustainability is having the least impact socially and environmentally with the currently available technology.

Why did you choose to work with denim? What opportunities lie in the denim sector?

I did not choose to work with denim, as much as denim choose to work with TENCEL™ Lyocell. There is a natural fit for denim to use TENCEL™ Lyocell, which I strive to accelerate and accentuate the use of. The opportunities in denim are endless. The consumer evolves and the industry evolves; there is a synergy.

Denim is one of the leading contributors of waste in the fashion industry. What can the denim industry do to reverse this trend?

First and foremost, we need to start addressing the aspect of consumption. There is too much product, too many promotions, and too many messages related to excessive purchasing. Additionally, the denim industry needs to assess ways to reduce water consumption from fiber to finished garment. There are technologies to support this which need to be scaled. Waste is the other contributor at post-industrial and consumer levels. From our current crisis have the opportunity to reflect and react on ways to reduce our environmental and social impacts.

Denim panel discussion at Bluezone, Munich, © Bluezone; Tricia Carey and Kerry Bannigan, Founder of Conscious Fashion Campaign at UN event 2019, © Conscious Fashion Campaign

How has COVID-19 affected your manufacturing process and/or your business partners along the supply chain?

COVID19 has devastated the apparel industry on a global scale. The safety and health of workers in factories, offices, and retail have been impacted. The greatest blow happened when the retailers in Europe and America closed which shut down supply chains in the East. The interdependence that we have between consumption and production is farfetched. In a positive way, many of our business partners are supporting the efforts to make masks, gowns, and other medical apparel to support. There is a kindness and empathy to support others.

Do you see the industry changing post-pandemic? If so, how?

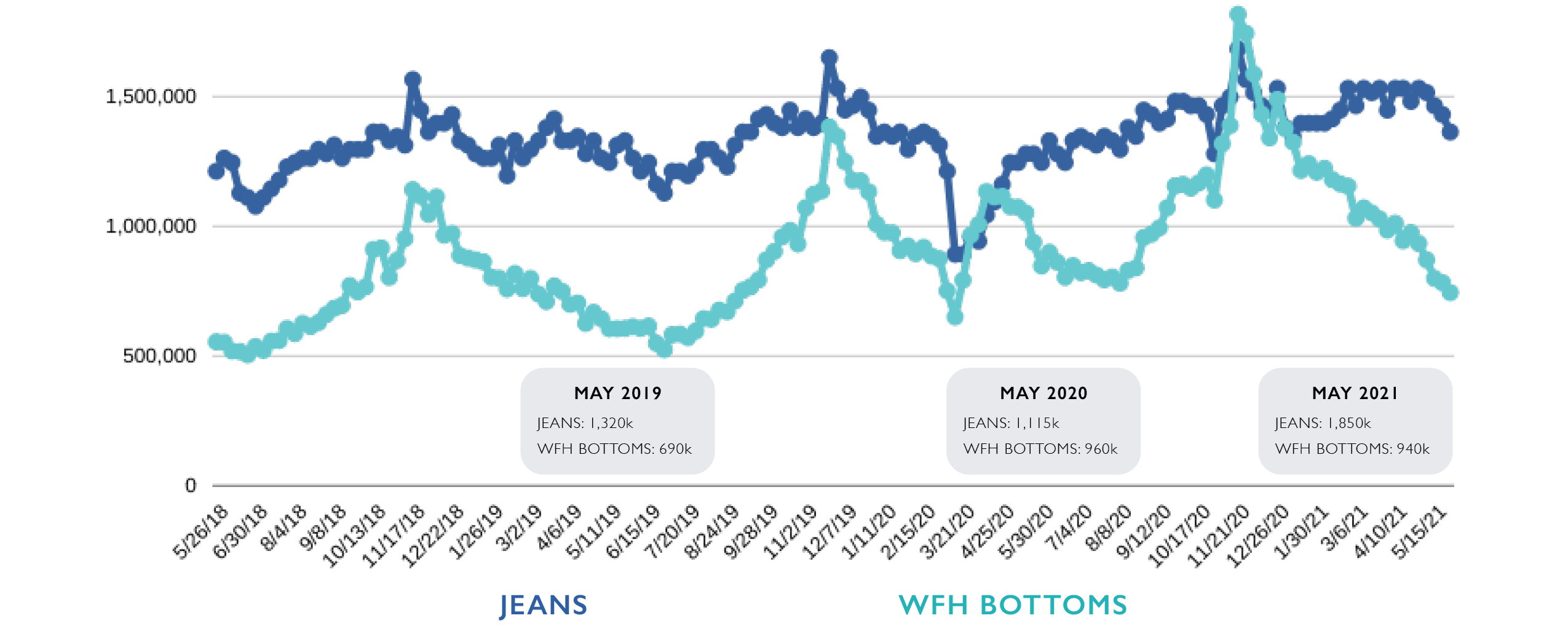

We highlight the Modern Definition of Denim and this current crisis will continue to shape global citizens, as well as the denim market. We are heading towards a massive transformation in an over-saturated apparel market. Businesses cannot go back to working the same ways and will have to change in order to thrive in the post-pandemic world. We cannot shut more than 1/3 of the world away for months and expect people to be the same. Consumers will have different demands after the crisis as they seek safety, security, and comfort. New trends will emerge on digital experiences, season-less styles, and performance wear. Social distancing have led to new ways of connecting.

Why is it so important for companies to invest in sustainable innovation? What advice would you give to those looking to invest?

If companies do not invest they will not be able to succeed in the future. The investments need to be considered for long-term business, not a short-term quick win.

REFIBRA™ Process, © LENZING™

What is REFIBRA™ technology? How does it help eliminate fiber waste?

TENCEL™ Lyocell with REFIBRA™ technology upcycles cotton waste to make a new fiber that has the same integrity as original TENCEL™ lyocell. The process takes post-industrial and post-consumer waste to make a pulp which is blended with wood pulp and then dissolved in a solvent.

What are some of the challenges that come with recycling fibers? How is Lenzing addressing those challenges?

The greatest challenge with recycling fibers is raising awareness at the consumer, brand, and supply chain levels. We need to accelerate the acceptance of textile-to-textile recycling with legislation and enforcement.

Does Lenzing use data in its decision making processes? If so, how?

Yes, we are the only wood-based cellulosic fiber producer to have approved Science-Based Targets; actually there are only 350 companies in the world. We use data to support our sustainability strategies and other business developments.

In your opinion, what is the future of textile sustainability?

It will be expected as the norm with the commercialization of technologies and further advances. Educating consumers about textiles, like they know about food, will support the advances.

What advice would you give your younger self?

Never stop dreaming.

If you’re interested in becoming a member and want to learn more about trends that are growing — and dying, please contact hello@trendalytics.co.